Large format printing, otherwise known as wide format printing is one of the most popular ways renters, home, and business owners can create graphics for decoration, advertising, and information. This medium allows for larger than life signs that speak to people in a way smaller prints can’t. Whether the viewer is standing 2 feet or 20 feet away, these awe-inspiring wall murals, vinyl banners, window wraps, and wall decals can offer aesthetic, as well as practical benefits in a variety of settings.

In order for our readers to know the basics about the large format, in this blog, we will lay out the most important aspects of a unique production process that’s now widely used in both commercial and residential surroundings.

Benefits of Large Format Printing include:

- Better Visual Field Coverage – A larger graphic is more likely to catch someone’s eye than a smaller posted bill or flyer.

- More Readability for Large Groups – Wide-format printing means many individuals will be able to read your sign at once, making them ideal for busy roads, heavily foot trafficked areas, and large spaces.

- Larger-than-Life Graphics – Large format allows for life-size or even “larger-than-life” sized images and text that can reach people on a deeper, more impactful level.

- Economical – More expensive methods such as fabricated channel letters, hand-painted signs and wall murals cost much more in both materials and labor — while large format prints offer the same benefits at a fraction of the cost.

The Printing Process

What Makes a Print Large Format?

While this may seem like an easy question, the exact line between small format and large format begins can sometimes be blurred. The term large format usually includes any print that is between 18” and 100” wide. Anything larger than 100” is often referred to as super wide or grand format. More simply put, the main difference between large and small format is that small format prints are meant to be read close up, often by just one or two individuals at a time, while the large format is made to be viewed from 2 feet or more away by many people at once. Think of how a letter, brochure, playbill or flier would be read versus a window wrap, street festival banner, or billboard.

How Does the Large Format Printing Process Work?

If you use an inkjet printer at home or a laser printer at the office, then you have a basic understanding of the process for producing large format prints. Toner or ink is applied to the product in order to provide a quicker production time, as well as a more seamless look than the traditional printing press used for newspapers.

What Kinds of Printers Are Used?

The three main types of printers used for large format print operations: flatbed, roll-to-roll or hybrid.

- Flatbed Printers – these are used by laying the printing surface, also known as a substrate, onto a horizontal bed which carries the material through the printer. To complete the process, UV light is used to dry the ink. This type of printer will be used for thicker substrates such as PVC, foam board, cardboard, metal and wood.

- Roll-to-Roll Printers – this type of printer is normally used for products such as canvas, vinyl banners, paper and other print substrates that come on rolls. The roll of blank material is loaded onto one end of the equipment, unrolled and passed through to the printer to be rolled back up on the other side. This method used for long runs of flexible material where uninterrupted speed is important.

- Hybrid Printers – a hybrid or combination printer incorporates both of these techniques into one versatile (and space-saving) piece of equipment. Both the flatbed and rolls are able to be attached, removed, and stowed away — as well as brought out of storage and re-attached as needed — in order to complete a wide variety of jobs using the same printer.

Why Do Printed Colors Look Different From How They Appeared on My Computer Screen?

Pantone® Color Matching and RGB vs. CMYK

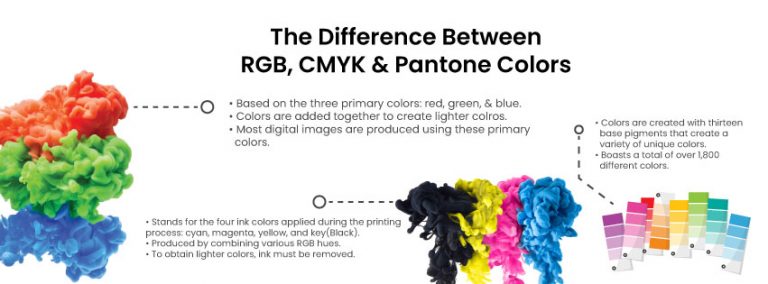

The color image you see on your computer screen is produced using the RGB color model. This method uses the three primary colors: red, green and blue which can produce any other color when combined. The RGB model is additive, meaning for example you are adding red to green to produce yellow.

Most printed material, on the other hand, is made using the CMYK color model. The name CMYK stands for the four colors used for color printing: cyan, magenta, yellow, and key (otherwise known as black). This method is subtractive, meaning you are removing ink to create lighter colors. The CMYK model also uses half-tones, or dots that are sized and spaced a certain to create a visual illusion. For example, the purple-ish red magenta can be half-toned to appear pink.

The reason why RGB colors on a screen often look different in printed form is simply that they look of RGB colors will always be based on precise display settings — making their appearance vary widely even between different computer monitors.

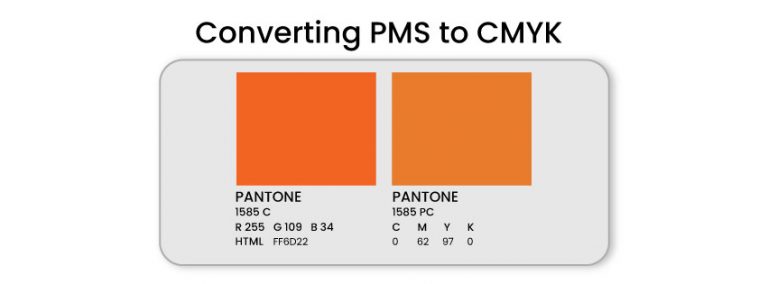

The Pantone Matching System (PMS) is widely used in marketing, fashion, as well as other industries because it allows for consistent color reproductions between digital and print media. Pantone does this by featuring over 1800 uniquely numbered colors.

This identification system allows companies anywhere in the world to confidently apply a precisely identified color, knowing exactly how it will appear on any printed material. The one drawback to Pantone Color Matching is its expense. Retaining Pantone colors requires more time for setup, cleaning, and in the case of traditional offset printing, additional plates.

If you want true PMS color reproduction for a project, it’s also important to use a reputable commercial print shop such as Brooklyn Signs. Many web-based consumer printing services will simply convert your PMS colors to CMYK, causing them to lose their brilliance.

Knowing Which Print Will Work for YOU

There are many choices available for your next large format project. The first thing to keep in mind is what your specific needs are. It’s useful to first consider how long you will need your graphic and where it will be hung, e.g. indoors or outdoors. Keep in mind if you’ll be hanging your graphic in direct sunlight, such as in a window or naturally bright room, you will want to go with a solvent-based ink, which will be more resistant to UV rays without fading.

The surface you’ll be installing your graphic on is also important. Non-porous surfaces such as glass will, a standard inkjet ink will not do, as it won’t adhere properly. UV-cured inks are usually better for this type of job. However, these inks can be scratched off with wear and tear. If your sign will require a high resistance to friction, such as transportation, that is something you should discuss with your printer.

Whether you’re creating a banner to hang from a banner stand, construction fence, or installing large vinyl wraps in your home and place of business, you will need to first consult an experienced graphics company such as Brooklyn Signs. They will walk you through the entire process in order to make sure all the right boxes are checked when it comes time to deploy your new graphic.

Still, Have Questions? Feel Free to Reach Out to Us.

In order to learn more about large format printing, contact the Brooklyn Signs by emailing info@brooklynsigns.com, calling (718) 252-7575, or simply fill out this form for a free quote